Features and benefits

- Gentle treatment and even distribution of the media provide the highest possible product output quality.

- High heat transfer efficiency and extended intervals between cleaning ensure operation for an entire campaign with minimum downtime and maximum value for money.

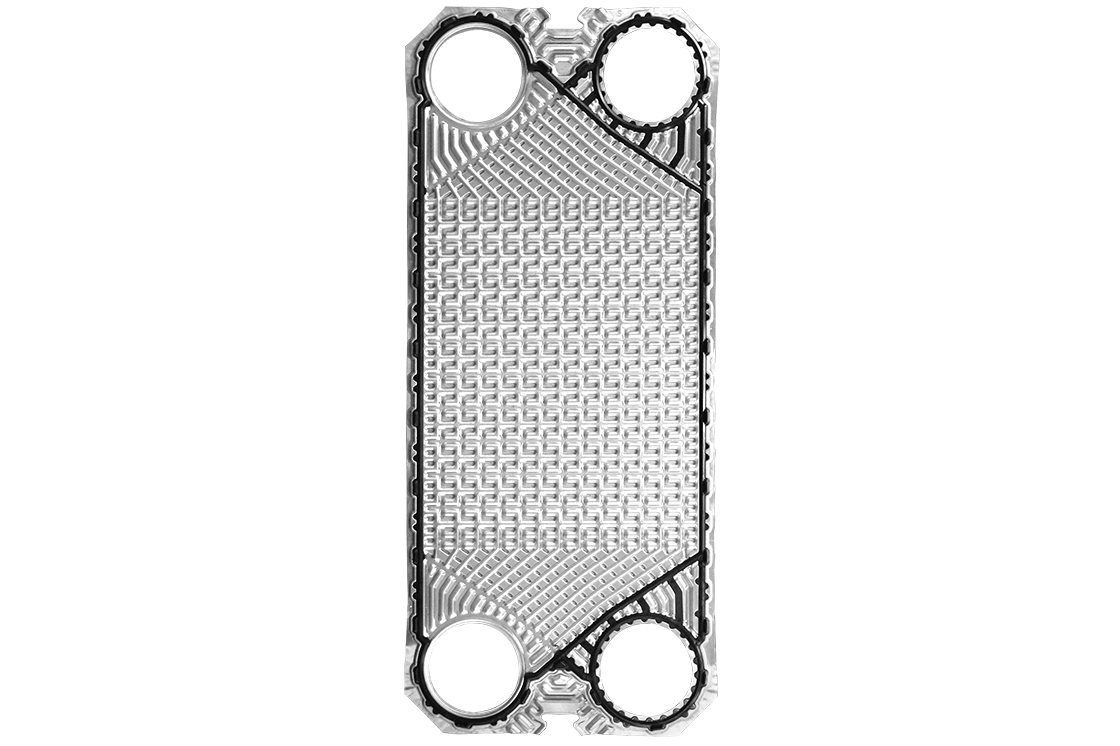

- Large plate gap designed to counteract fouling with sizeable plate channels and no stagnant zones.

Applications

- Dairy/food/beverage industry

– e.g. food production, like juice and alcohol processing - Sugar industry

– e.g. sugar production, such as concentration of sugar content in sugarcane juice - Biogas industry

- Wastewater industry

- Pulp and paper industry

- Mining industry

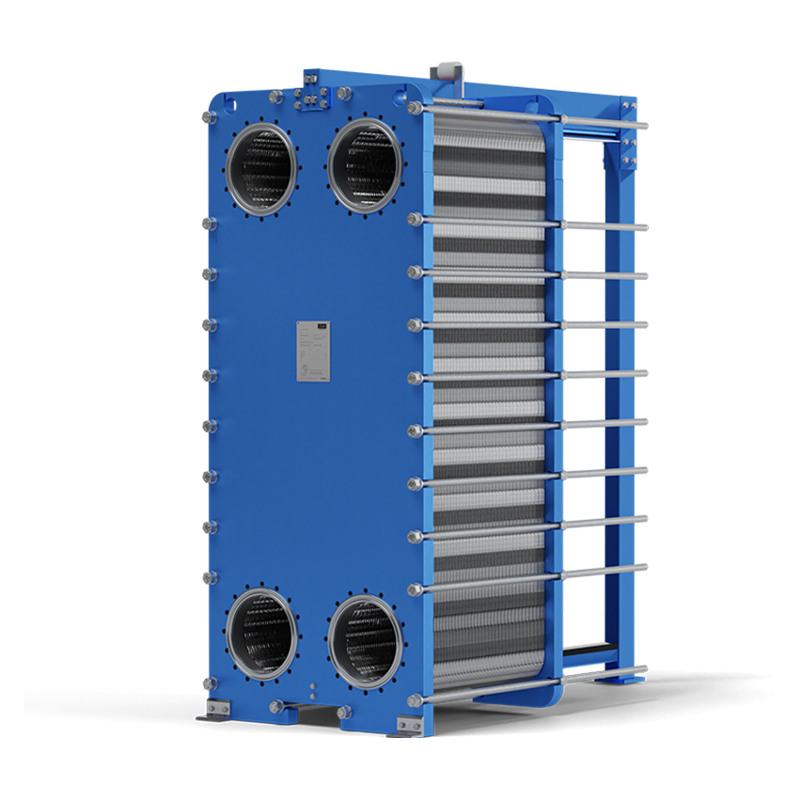

Technical specifications

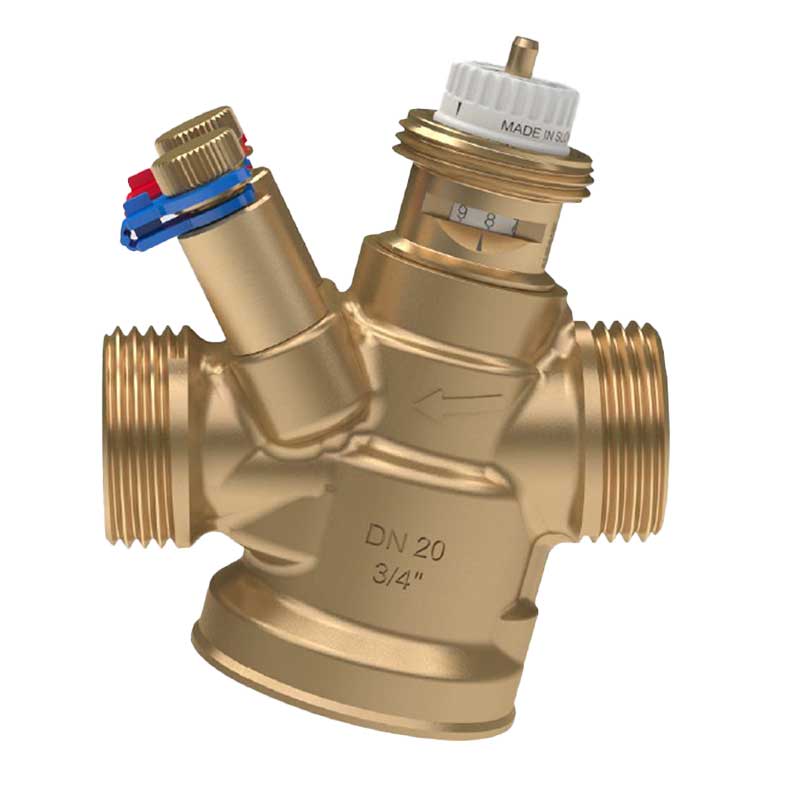

- Connections from DN25 to DN500 (1” to 20”)

- Frames designed according to FEA and PED 2014/68/EU (EN13445) and ASME sec VIII, Div. 1 construction standards

- Plate materials: AISI 304/316, titanium, SMO, Hastelloy*

- Gasket materials: EPDM-HT, NBR-HT, Viton*

- Plate heights up to 3.5 m (11.5 ft)

- Flow rates up to 1,600 m3/h (7,045 gpm)

- Plate gap from 5 to 12 mm (0.2” to 0.5”)

- Working pressure up to 10 bar (145 psi)

- Working temperatures from -20 °C to 180 °C (-4 °F to 356 °F)

*other materials available upon request