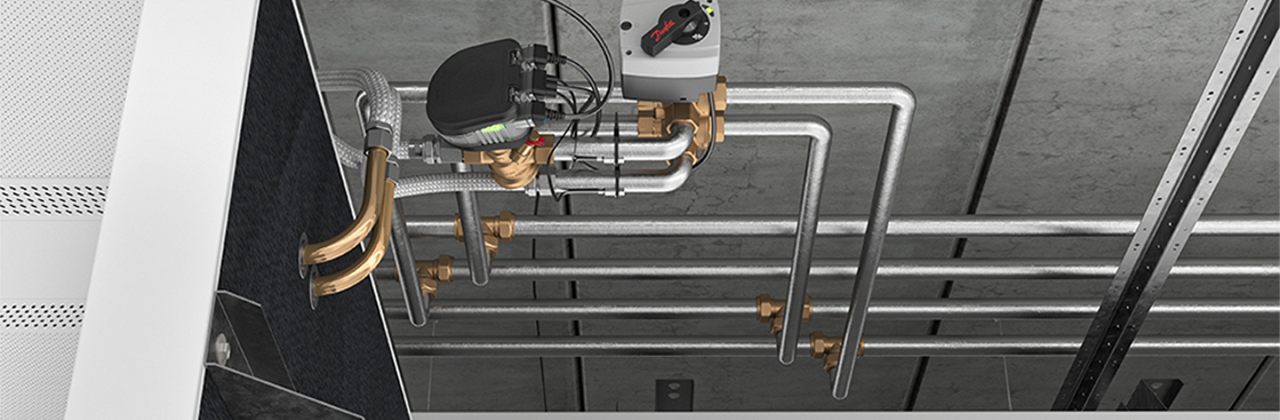

All the information provides System Integrators and technical facility managers a unique insight in, and remote access to, the HVAC system. The actual HVAC data can be used to optimize the systems performance, improving the indoor comfort and achieve an energy efficient building.

NovoCon® is an essential device in the transition to HVAC 4.0 for smart, connected buildings. The actuators enable continuous monitoring, active energy management and preventive maintenance at the highest comfort level and lowest operating costs. The digital actuators can be used in many building types such as offices, hotels and hospitals. But also in cruise ships, universities, data centers, shopping malls, museums or supermarkets.

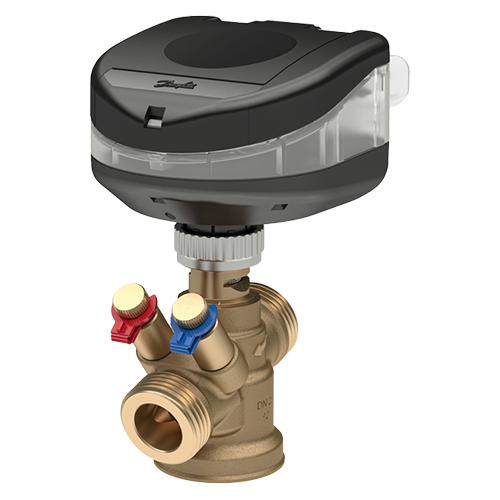

NovoCon® series digital IoT actuators

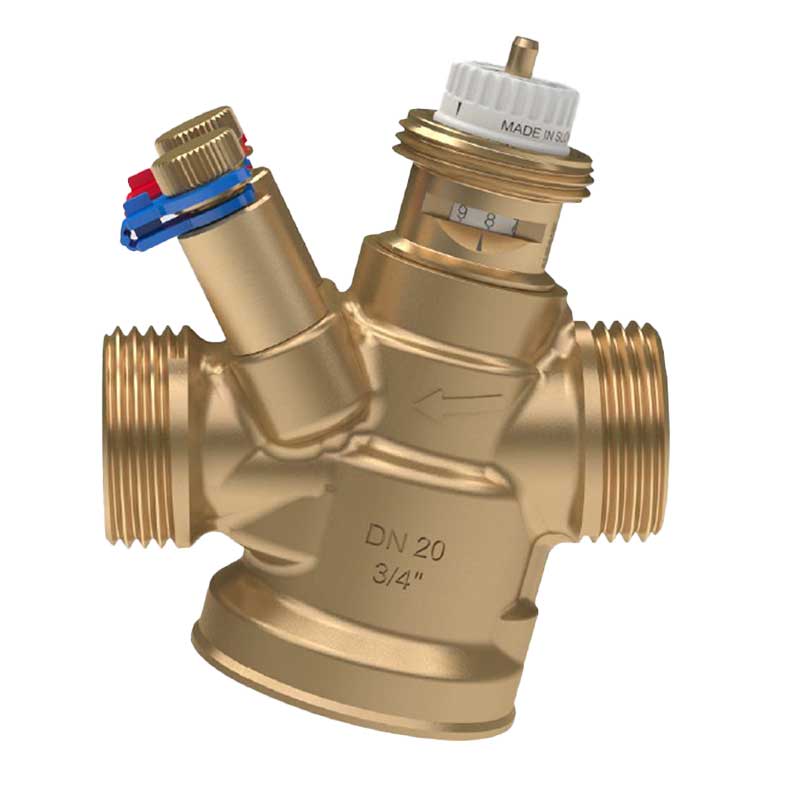

Danfoss NovoCon® series of digital actuators for PICVs consists of four versions;

- NovoCon® S fits AB-QM valves DN 10-32 and new AB-QM 4.0 valves DN 15-32. These combinations are applicable for various types of Terminal Units such as Fan Coil Units (FCU), chilled beams and radiant panels. The valves are used in two-pipe heating or cooling and four-pipe heating/cooling change-over systems for flows from 20-4,000 l/h.

- For fast and reliable installation the NovoCon® S can only be connected to the BMS and wired in daisy-chain by using our series of plug & play connection cables

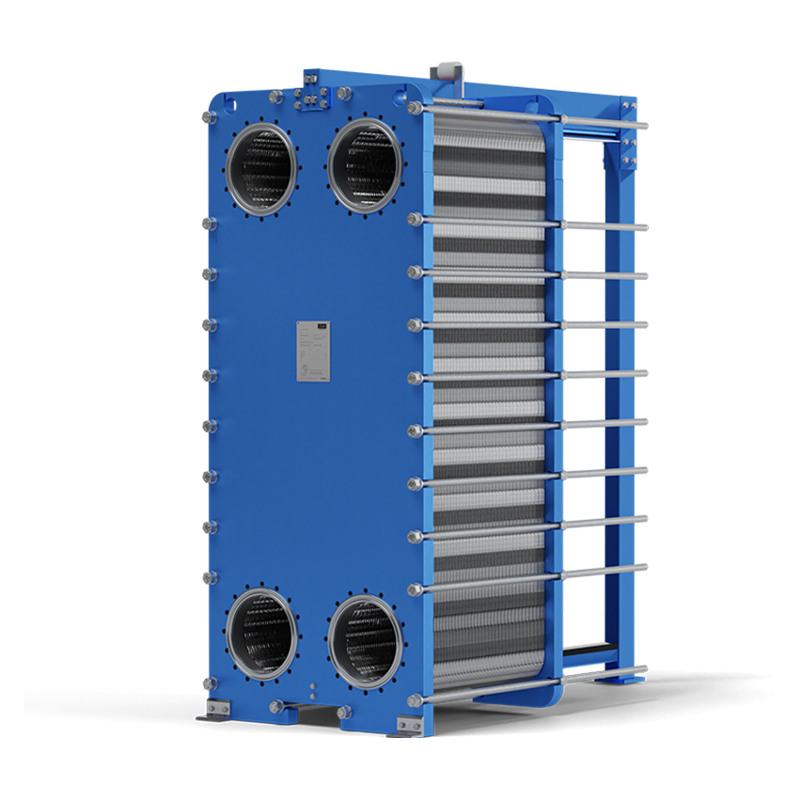

- NovoCon® M fits dedicated AB-QM NovoCon® valves DN 40-100. These combinations are applicable for the control of higher volume flows from 3-59 m3/h in e.g. Air Handling Units (AHU).

- NovoCon® L fits AB-QM valves DN 125-150. These combinations are applicable for the control of high volume flows from 36-190 m3/h in e.g. chiller applications.

- NovoCon® XL fits AB-QM valves DN 200-250. These combinations are applicable for the control of the highest volume flows from 80-370 m3/h in e.g. District cooling applications.

Built-in I/O

The digital actuators also offers built-in I/O’s for added functionality, flexibility and cost savings. In some applications this can replace I/O modules from the BMS. A few examples of using the actuators’ I/O’s are:

- Flow & energy indication by connecting sensors for return and supply temperature measurement with NovoCon® Energy

- Optimized solution for 4-pipe change-over applications with NovoCon® CO6 (only for NovoCon® S)

- To connect different sensors (e.g. room temperature, humidity, or condensation) and control different devices such as fans with NovoCon® Remote I/O cable.

Features and benefits

Remote access

Via the BMS system and bus communication all actuators can be remotely accessed. This saves a lot of time during the installation and commissioning of the system as well as during the many years the building is operational.

Continuous commissioning

System data can be retrieved and analyzed in order to optimize the HVAC system. In case adaptions to e.g. setting of design flows are required, it can easy be done. On one, a few or all actuators at the same time. Continuously monitoring and commissioning the system saves time and costs throughout the life cycle of the building.

Predictive maintenance

Don’t wait for HVAC components to fail, cause complaints and need for urgent and disturbing service activities. Instead you can see where and when an issue might occur and you can take precautions and act pro-actively.

Flexibility all over

The designers or system integrators of BMS systems can realize customized HVAC solutions for every project. In case the building user wants to refurbish the building, the HVAC system can be adapted accordingly without physical adjustments to the BMS components.